As infrastructure ages and global demand rises, ensuring safety, functionality, and efficiency has become an increasingly complex challenge.. Built decades ago, much of this critical infrastructure lacks detailed as-built documentation, complicating efforts to assess, maintain, and modernize these assets. Enter 3D scanning technology—a game-changing solution that combines precision, efficiency, and cost-effectiveness to address the unique challenges of documenting aging infrastructure.

This white paper explores the benefits of 3D scanning for aging infrastructure, focusing on cost savings, enhanced safety, and environmental stewardship. Through specific use cases and industry insights, we demonstrate why this technology is essential for managing infrastructure in the 21st century.

The Problem: Aging Infrastructure and Insufficient Documentation

Many critical infrastructures, including bridges, pipelines, industrial plants, and historic buildings, were built at a time when digital documentation and modern construction techniques were nonexistent. As a result, these assets often lack reliable accurate as-built records, CAD drawings, or BIM models. This documentation gap leads to challenges in:

- Planning maintenance and upgrades

- Ensuring safety and regulatory compliance

- Assessing structural integrity

- Managing resources effectively

Traditional inspection methods, such as visual assessments or physical measurements, are time-intensive, costly, and prone to human error. The need for innovative solutions to address these challenges has never been more critical.

The Solution: 3D Models as a Foundation for Digital Transformation

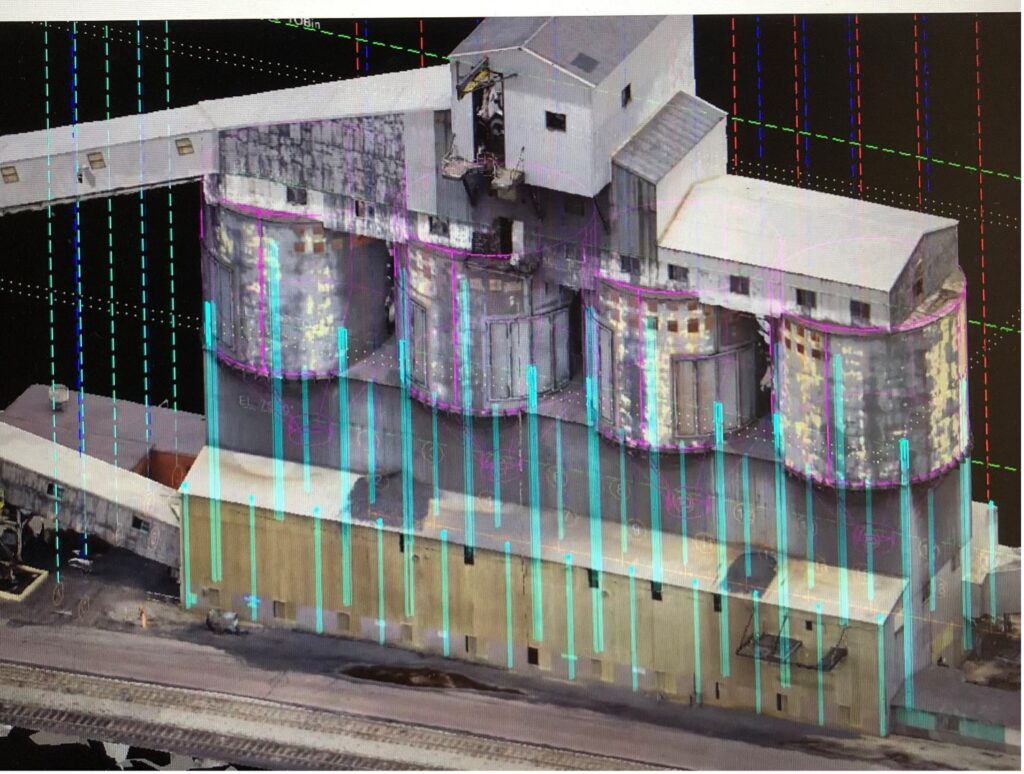

Eye-bot’s innovative approach provides high-precision 3D models of assets, capturing their as-is conditions in unprecedented detail. Different from most traditional laser scanning, Eye-bot leverages a range of remote sensing devices including DSLR cameras, drones, laser scanners, and survey-grade GPS to provide a more robust 3D deliverable, in a fraction of the time of scan only methods.

Key Features of Eye-bot’s Solution:

- Comprehensive Data Outputs: Each project includes ortho-images, 360° ground and aerial images, point clouds, surface models, and mesh models. All data is geolocated for verifiable accuracy.

- Advanced Data Fusion: Ground and aerial data are merged seamlessly, providing a cohesive, high-fidelity deliverable.

- Efficiency: Eye-bot reduces on-site time by 50% compared to traditional methods, thanks to its use of multiple sensor types and automated workflows.

- Automation: Eye-bot leverages advanced workflows which allow for automation of data collection, increasing the value and reliability of long-term monitoring solutions.

Key Benefits of 3D Scanning for Aging Infrastructure

- Enhanced Accuracy and Comprehensive Documentation

3D scanning delivers a level of precision that traditional methods cannot match. For instance, the NavVis VLX scanner generates dense 360-degree point clouds and panoramic images, allowing engineers to detect subtle structural deformations or cracks. This level of detail ensures that maintenance decisions are based on accurate and comprehensive data.

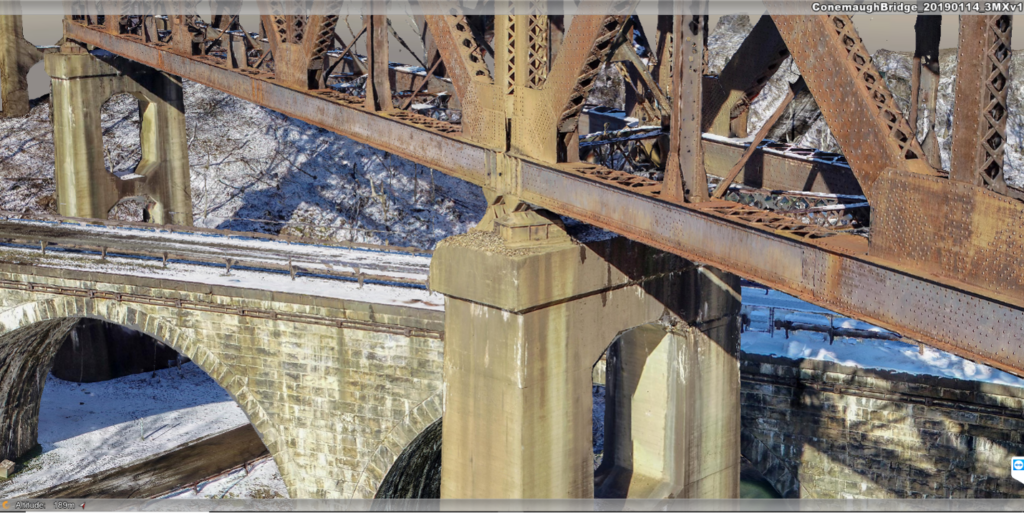

Example: A major bridge in Pennsylvania used 3D scanning to assess structural wear, enabling early detection of corrosion and preventing costly repairs down the line. The scan’s accuracy provided engineers with the confidence to implement targeted interventions, reducing unnecessary material use and costs.

Aerial Solutions to our Infrastructures Aging Problems | Eye-bot

2. Cost Savings Through Efficiency

By reducing time on-site and streamlining data collection, 3D scanning minimizes labor and travel expenses. Additionally, precise data enables more effective planning, preventing over-engineering and optimizing resource allocation.

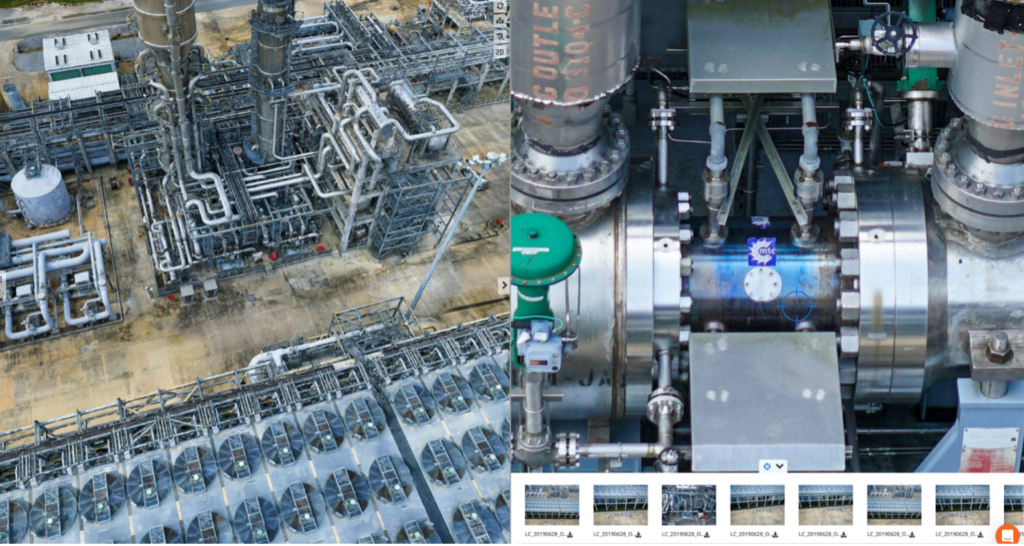

Example: An industrial plant in Louisiana utilized 3D scanning to update its outdated P&IDs and plan for equipment upgrades. The project’s time on-site was reduced by 50% compared to traditional survey methods, saving over $100,000 in labor and logistics costs.

3. Environmental Benefits

3D scanning plays a critical role in supporting Spill Prevention, Control, and Countermeasure (SPCC) and Stormwater Pollution Prevention Plan (SWPPP) compliance. High-resolution surface models and topographic data enable precise calculations of secondary containment volumes and water runoff patterns. This ensures that facilities meet regulatory requirements while minimizing environmental impact.

Example: A petroleum storage terminal in Louisiana used 3D scanning to calculate accurate secondary containment volumes for its SPCC plan. The data also facilitated the development of a SWPPP by identifying water flow paths and potential erosion areas, reducing the risk of stormwater contamination. This proactive approach helped the facility avoid regulatory fines and improved its environmental footprint.

3D Drone Visualization – Environmental Case Study | Eye-bot

4. Improved Safety

Offshore oil and gas platforms present unique challenges for inspection, maintenance, and decommissioning. 3D scanning provides a safe and efficient solution for assessing these aging structures, ensuring accurate documentation of structural conditions and guiding decommissioning efforts.

- Pre-Decommissioning Assessment: 3D scanning captures highly detailed models of offshore structures, identifying structural weaknesses, corrosion, and hazardous areas before dismantling begins.

- Regulatory Compliance: Offshore decommissioning projects must comply with strict environmental and safety regulations. 3D models provide precise documentation to support regulatory submissions.

- Cost Reduction: Detailed scans optimize decommissioning planning, reducing unexpected challenges and minimizing unnecessary work.

Example: In the Gulf of Mexico, a major operator utilized 3D scanning to document an aging offshore platform before decommissioning. The scan data allowed for precise planning, reducing project timelines, and ensuring safe dismantling while meeting regulatory standards.

Confined Space Inspections, What’s the Best Approach? | Eye-bot

5. Enhanced Collaboration and Digital Twins

The detailed models generated by 3D scanning serve as a single source of truth, enabling seamless collaboration among stakeholders. These models form the foundation for digital twins, which integrate IoT data and analytics for real-time monitoring and decision-making.

Example: A water treatment facility in Florida used 3D scans to create a digital twin, enabling real-time monitoring of pump efficiency and structural integrity. The digital twin’s insights led to a 20% reduction in energy consumption and extended equipment lifespan.

The evolution of the Digital Twin | Eye-bot

6. Facilitating Efficient Turnarounds through Advanced Work Packaging (AWP) and Management of Change (MOC)

Turnarounds—planned periods when a plant or facility is shut down for maintenance—are critical for ensuring the longevity and safety of aging infrastructure. 3D scanning plays a pivotal role in supporting AWP and MOC processes during turnarounds.

Advanced Work Packaging (AWP): AWP is a best practice that structures the flow of detailed work packages throughout an EPC (Engineering, Procurement, and Construction) project, from initial planning through to construction execution. 3D scanning provides accurate, up-to-date models that inform the creation of Construction Work Packages (CWPs), Engineering Work Packages (EWPs), and Installation Work Packages (IWPs), ensuring that all stakeholders have access to the same precise information. This alignment enhances productivity and reduces rework. (autodesk.com)

Management of Change (MOC): MOC is a systematic approach to managing safety risks associated with changes in process chemicals, technology, equipment, and procedures. Continuous updates from 3D scanning allow for real-time documentation of site changes, ensuring that any modifications are accurately captured and assessed for potential risks. This proactive approach maintains safety and compliance standards.

Example: During a turnaround at a petrochemical plant, 3D scanning was used to capture the as-is conditions of the facility. This data informed the development of detailed work packages, aligning engineering and construction teams. As changes occurred on-site, the 3D models were updated in real-time, supporting effective MOC processes and ensuring that all modifications were documented and evaluated for safety implications.

Dimensional Control Used for Construction Verification | Eye-bot

Challenges and Considerations

While 3D scanning offers numerous advantages, it is essential to address challenges such as:

- Initial investment in equipment and training

- Data management and storage requirements

- The need for skilled personnel to interpret complex datasets

- Continuously changing technology

However, these challenges are outweighed by long-term benefits in cost savings, safety, and environmental sustainability.

As the energy industry grapples with the challenges of aging infrastructure, accurate and accessible 3D models are becoming indispensable. Eye-bot’s cutting-edge technology and expertise empower companies to overcome these challenges, providing a cost-effective, proven, and safe solution to document and manage critical assets.

By investing in 3D models, companies can reduce costs, enhance safety, and drive collaboration—ultimately extending the life of their assets and enabling a more sustainable future. With Eye-bot as a trusted partner, the possibilities are limitless.

About Eye-bot

Eye-bot has been a trusted partner to industry-leading energy companies since 2017, delivering state-of-the-art drone services and 3D scanning solutions in over 20 countries. With a proven track record of innovation and excellence, Eye-bot is redefining the future of asset management and digital transformation.

For more information, visit eye-bot.com.